Medical waste incinerators are designed for the safe and controlled disposal of waste generated in healthcare, laboratory, pharmaceutical and research environments. These systems enable the effective treatment of infectious, pathological, and potentially hazardous waste that requires special handling and destruction procedures.

The use of industrial incinerators ensures the complete destruction of harmful microorganisms and hazardous substances at high temperatures, with controlled process parameters and reduced emissions. This guarantees a high level of biosecurity and minimizes the risk of contamination of people, equipment, and the environment.

Incinerators are used in hospitals, clinics, laboratories, veterinary facilities, and industrial systems where reliable and legally compliant medical waste disposal is essential. The systems are adaptable to various capacities and waste types, allowing their application in smaller healthcare facilities as well as in larger centralized treatment plants.

Medical and infectious waste is considered high-risk due to the potential spread of infectious diseases, environmental contamination, and risks to human health. For this reason, its disposal is subject to strict legal, safety, and hygiene requirements that regulate the collection, treatment, and final destruction of waste.

Incineration of medical waste in industrial incinerators ensures the complete destruction of infectious and hazardous substances at high temperatures, with a controlled process and reduced emissions. These systems are designed in accordance with applicable regulations and enable safe and reliable waste disposal in healthcare and industrial environments.

The use of certified incineration systems ensures compliance with regulatory requirements, reduces the risk of secondary contamination, and enables healthcare facilities, laboratories, and operators to manage medical waste safely throughout the entire disposal process.

Similar biosecurity and regulatory principles also apply to animal waste disposal, where control of the incineration process is critical to preventing the spread of infectious risks.

In situations where constructing a permanent facility is not feasible or cost-effective, prefarbricated incinerator housing units (shelters), enable the rapid establishment of a controlled and legally compliant environment for medical waste disposal.

Due to strict emission and safety requirements, the incineration of medical and infectious waste requires advanced flue gas treatment systems.

Medical waste incinerators represent the safest and most effective method for disposing of infectious and hazardous waste generated in healthcare and laboratory environments. Controlled high-temperature incineration ensures the complete destruction of pathogens, microorganisms, and harmful substances that may pose a risk to human health and the environment.

Unlike alternative waste treatment methods, incinerators enable immediate and on-site disposal of medical waste, reducing risks associated with the transport, storage, and handling of infectious materials. This approach increases safety within healthcare facilities and provides greater control over the entire disposal process.

The systems are designed for various capacities and types of medical waste and can be adapted to the specific needs of hospitals, clinics, laboratories, and industrial users. In the long term, the use of incinerators provides a stable, reliable, and legally compliant solution that supports responsible medical waste management.

Solutions for the disposal of medical and infectious waste are adapted to a wide range of healthcare, research, and industrial systems, including:

In extraordinary circumstances—such as temporary healthcare facilities, crisis situations, or epidemics - mobile medical waste disposal solutions can be deployed alongside fixed systems. These solutions enable autonomous and safe operation without reliance on existing infrastructure.

Due to strict regulatory and safety requirements, it is essential to conduct professional waste management consultation prior to implementing a medical waste incineration system, in order to ensure full compliance and the optimal technical solution.

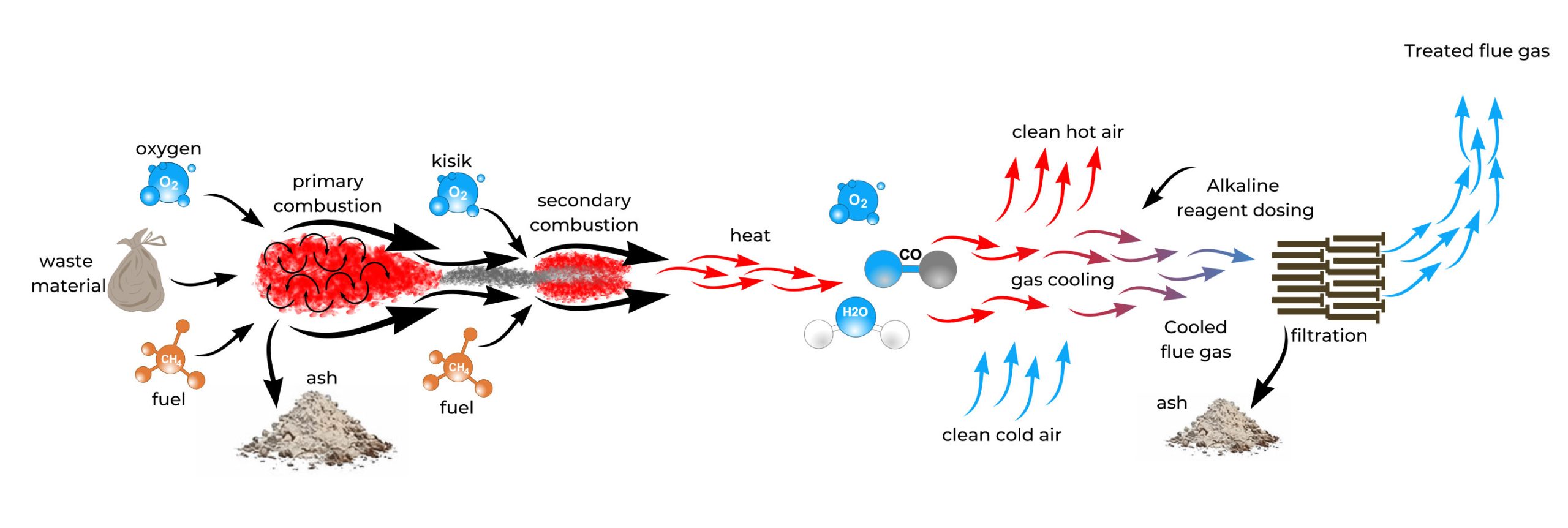

The medical waste incineration process is carried out in clearly defined and controlled stages, ensuring the safe destruction of infectious and hazardous substances while minimizing environmental emissions.

Waste Loading

Waste is loaded using an automatic loading and dosing system, ensuring controlled and safe handling of medical waste without direct contact between personnel and hazardous materials. The waste is first introduced into a cold loading chamber, from which it is automatically transferred into the combustion chamber.

Primary Combustion

A precisely controlled amount of fuel and oxygen is introduced into the primary combustion chamber to achieve optimal combustion conditions. Incineration takes place at high temperatures, ensuring the complete destruction of infectious materials. The resulting ash is automatically removed using a hydraulic ash removal system.

Secondary Combustion

Flue gases are then directed into a secondary chamber where, through high-temperature retention combined with the additional supply of tertiary air and fuel, secondary combustion is performed. This stage ensures further breakdown of harmful gases and stabilization of the combustion process.

Flue Gas Cooling and Thermal Energy Recovery

Following secondary combustion, the flue gas is cooled in a heat exchanger to temperatures outside the so-called dioxin temperature window, preventing the reformation of dioxins and furans after flue gas treatment. During this process, a large volume of clean heated air is generated, which—depending on system configuration—can be utilized for space heating, technological processes, or further conversion into useful energy.

Acid Gas Neutralization

An alkaline reagent is then dosed into the cooled flue gas to neutralize acidic gases, further reducing the environmental impact of emissions.

Flue Gas Filtration

Finally, the flue gas passes through a ceramic filtration system with automatic cleaning of the filter elements and separation of remaining particulate matter and ash.

Discharge of Treated Flue Gas

Only after passing through all treatment and filtration stages is the treated flue gas safely released into the atmosphere, in full compliance with the strictest emission regulations and standards.

The same core technology is also used in the treatment of hazardous industrial waste, with system capacity and configuration adapted to specific industrial requirements.

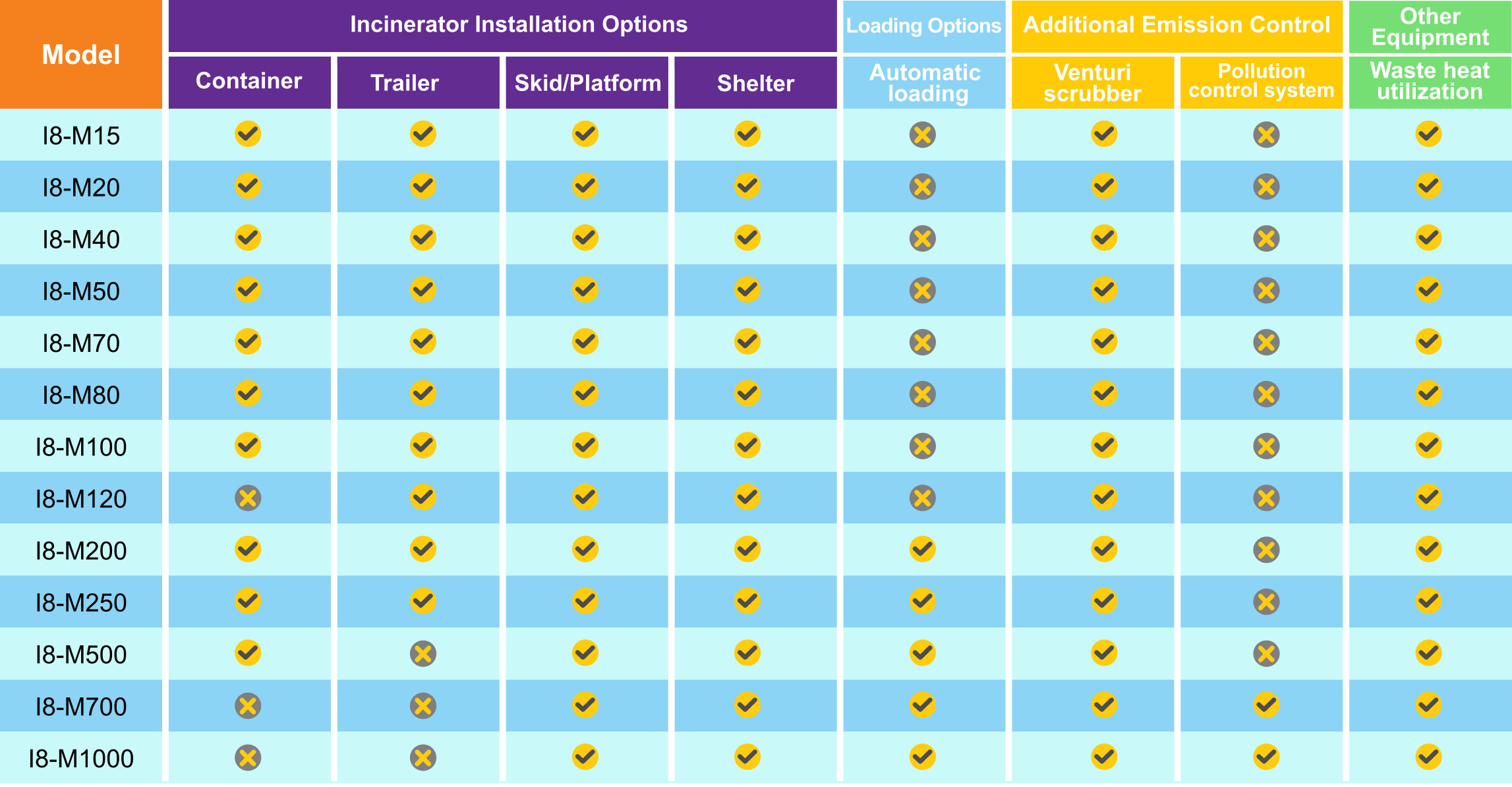

Selecting the appropriate system for the disposal of medical and infectious waste is not simply a matter of choosing a specific model, but rather understanding the actual operational requirements. In practice, the optimal solution depends on several key factors that together define the technical and functional needs of the system.

When defining the appropriate solution, the following factors are considered:

Type of Waste

Different categories of medical and infectious waste require different treatment approaches, operating temperatures, and additional safety measures.

Daily Throughput

The volume of waste processed on a daily basis directly influences system sizing and configuration selection.

Operating Regime

Continuous or intermittent operation, the number of daily cycles, and required operational flexibility are important factors in system selection.

Local Regulations

Regulatory and technical requirements vary depending on the country and location and may affect the need for additional components and specific system configurations.

Based on these parameters, it is possible to define a technically justified and operationally efficient solution tailored to real working conditions. Rather than offering universal recommendations, we approach each project individually, taking into account all relevant technical and organizational aspects.

Selecting the appropriate system for the disposal of medical and infectious waste is not simply a matter of choosing a specific model, but rather understanding the actual operational requirements. In practice, the optimal solution depends on several key factors that together define the technical and functional needs of the system.

When defining the appropriate solution, the following factors are taken into account:

Type of Waste

Different categories of medical and infectious waste require different treatment approaches, operating temperatures, and additional safety measures.

Daily Throughput

The volume of waste processed on a daily basis directly influences system sizing and configuration selection.

Operating Regime

Continuous or intermittent operation, the number of daily cycles, and required operational flexibility are important factors in system selection.

Local Regulations

Regulatory and technical requirements vary depending on the country and location and may influence the need for additional components and specific system configurations.

Based on this information, a technically justified and operationally efficient solution can be defined, tailored to real operating conditions. Rather than offering universal recommendations, we approach each project individually, taking into account all relevant technical and organizational aspects.

Medical waste disposal systems form part of a broader portfolio of waste incinerators and thermal waste treatment solutions designed for various sectors.

The EU Waste Incineration Directive establishes strict operating conditions, technical requirements, and emission limits for plants that thermally treat waste, in order to protect the environment and human health. The Directive requires permits and continuous monitoring, ensuring modern waste treatment systems meet high environmental standards

For more information …

Contact us

Follow Us

Quick Links