Municipal and industrial waste incineration solutions are part of our comprehensive portfolio of waste incinerators and thermal treatment systems tailored to diverse sectors and operational requirements.

In the incineration of municipal and hazardous industrial waste, continuous operation enables efficient integration of waste heat recovery systems, converting thermal energy from the process into usable energy for space heating, technological processes, or hot water production.

When incinerating municipal and hazardous industrial waste, flue gas treatment plays a critical role in emission control and compliance with strict environmental regulations.

Our municipal and industrial waste disposal solutions are used across a wide range of public and private systems, including:

Municipal companies and city waste management services

Industrial zones, manufacturing facilities, and infrastructure sites

Waste management and treatment operators

Waste processing plants and regional recycling centers

Energy facilities and critical infrastructure

Ports, logistics centers, and customs zones

Tourism complexes and resorts with increased seasonal demand

Migration, humanitarian, and emergency camps

Remote and isolated operations, including mines, research, and scientific bases

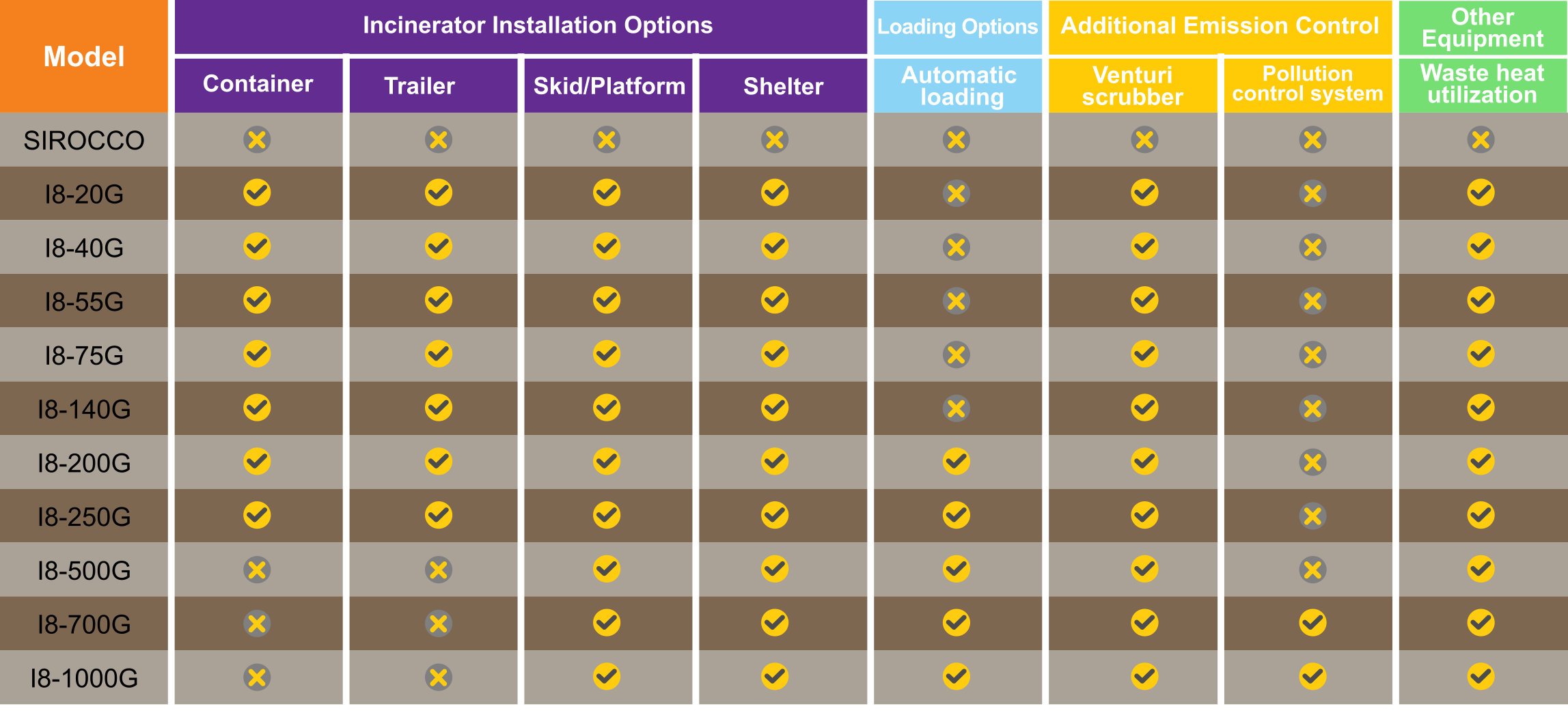

Solutions are adapted to various waste types, operational capacities, and regulatory requirements, with a strong emphasis on safety, reliability, and long-term system efficiency.

A specific category within industrial waste streams includes animal waste disposal systems, which require additional biosecurity measures and tailored system configurations.

Customized versions of these systems are also used for the development of pet cremation services, where emphasis is placed on an individual and dignified approach.

In projects involving temporary locations, limited infrastructure, or crisis situations—such as temporary camps, migration centers, and post-disaster recovery—mobile municipal and industrial waste disposal solutions can be deployed, offering rapid implementation and high operational flexibility.

In industrial and municipal projects where rapid system deployment is required or site constraints exist, prefabricated incinerator housing units (shelters) provide a reliable solution without the need for extensive construction works.

The incineration of municipal and industrial waste is carried out through clearly defined and strictly controlled stages, ensuring the safe destruction of hazardous substances, significant waste volume reduction, and legally compliant emissions. The systems are designed to process various waste types, including municipal, technological, and hazardous industrial waste.

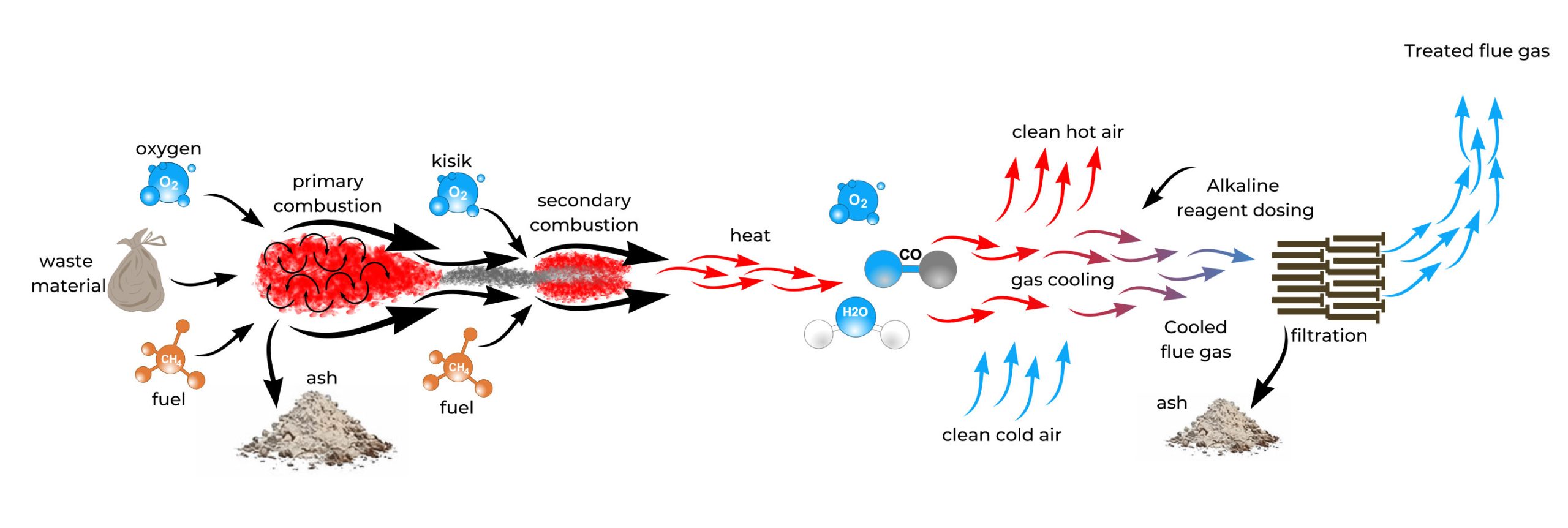

Waste Loading and Dosing

Waste is loaded using an automatic loading and dosing system, ensuring safe and controlled handling. Depending on the type and composition of the waste, the system allows adjustment of the dosing method to maintain stable combustion conditions and maximize process efficiency.

Primary Combustion

Waste is introduced into the primary combustion chamber, where precisely controlled fuel and oxygen supply create optimal combustion conditions. Incineration takes place at high temperatures, enabling effective destruction of hazardous and harmful substances while significantly reducing waste volume. The resulting ash is automatically removed using a hydraulic ash removal system.

Secondary Flue Gas Combustion

Flue gases from the primary chamber are directed into a secondary chamber, where they are retained at high temperatures with the additional supply of tertiary air and fuel. This stage ensures further oxidation of remaining organic compounds and stabilization of the combustion process, which is particularly important when incinerating hazardous industrial waste.

Flue Gas Cooling and Thermal Energy Recovery

After secondary combustion, the flue gas is cooled in a heat exchanger to temperatures outside the so-called dioxin temperature window, preventing the reformation of dioxins and furans. During this process, a significant amount of clean heated air is generated, which—depending on system configuration—can be used for space heating, technological processes, or other energy applications.

Acid Gas Neutralization

An alkaline reagent is dosed into the cooled flue gas to neutralize acidic gases generated during incineration, further reducing environmental impact and ensuring compliance with applicable regulations.

Filtration and Treatment

The flue gas then passes through an advanced ceramic filtration system with automatic cleaning of filter elements and separation of remaining particulate matter and ash. This system ensures a high level of flue gas purification prior to discharge.

Safe Atmospheric Discharge

Only after passing through all combustion and treatment stages is the treated flue gas safely released into the atmosphere, in compliance with the strictest emission regulations applicable to municipal and hazardous industrial waste incineration.

The same process control and flue gas treatment principles also apply to medical waste disposal, where regulatory requirements are particularly stringent.

Remote communities, local government authorities, and business entities face numerous challenges in waste management systems, including:

These challenges are particularly pronounced in isolated or hard-to-access areas, where traditional waste management approaches become logistically impractical or economically unsustainable.

In municipal and hazardous industrial waste disposal projects, professional waste consultancy helps define the optimal technology, system capacity, and regulatory-compliant approach from the outset.

For more information …

Contact us

Follow Us

Quick Links